Technofist

Composite Materials Projects and training for Engineering Students in Bangalore, Composite Materials mechanical projects 2018-19

At TECHNOFIST, we provide academic projects based on COMPOSITE MATERIALS with the latest papers implementation. Below mentioned are the 2018 list and abstracts in the COMPOSITE MATERIALS domain. For synopsis and IEEE papers, please visit our head office and get registered.

OUR COMPANY VALUES

Instead of Quantity, we prefer Quality, Commitment, and Success.

OUR CUSTOMERS

Our customers are delighted with the business benefits of the Technofist Engineering solutions.

2018-2019 LATEST COMPOSITE MATERIAL BASED PROJECTS

- Composite material concepts which prove to provide high-performance products that need to be lightweight yet strong enough to take harsh loading conditions. A best example is that airship bodies are built out of composites. Composites like E-glass reinforced with Jute give very good strength and lightweight composite. This category consists of Composite Material 2018-19 project list with abstract/synopsis. Here we provide the latest collection of topics developed using the latest designs and concepts. Latest Composite Material concepts for Diploma and Engineering students, Composite Material project centres in Bangalore with high-quality training and development.

FINAL YEAR PROJECT LIST

COMPOSITE MATERIALS BASED PROJECT ABSTRACT

IEEE 2018-19 composite materials projects list for BE/Diploma/M.TECH in Bangalore.

| Code | Description |

|---|---|

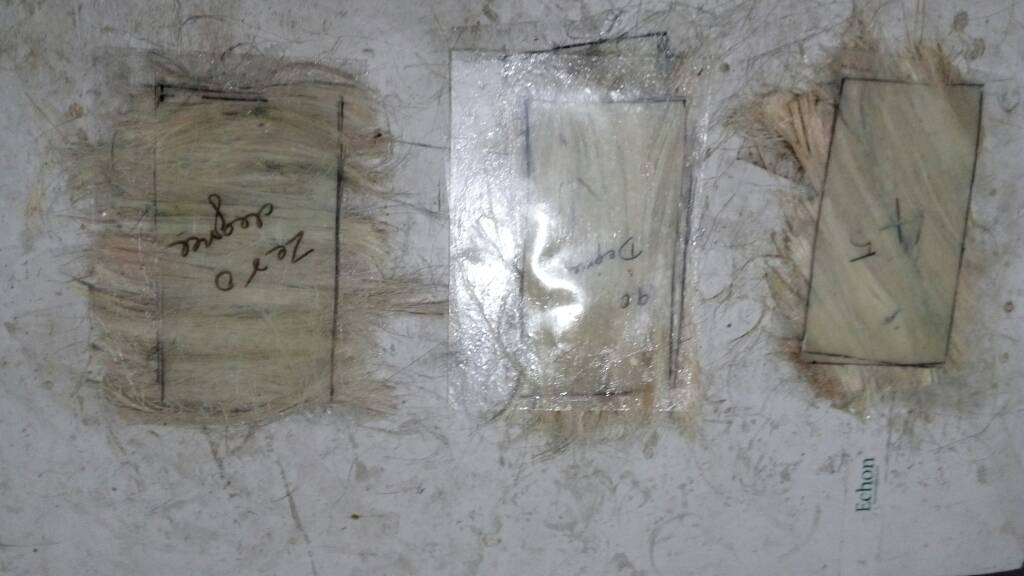

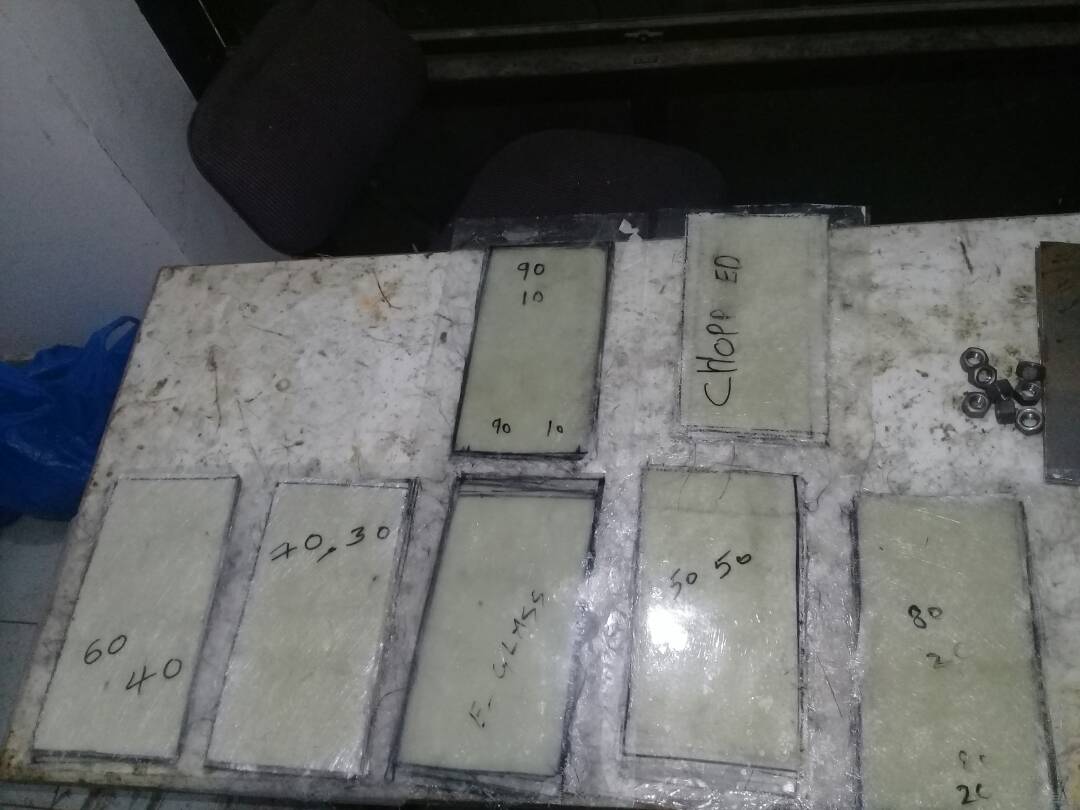

| TCM001 | DEVELOPMENT OF COMPOSITE USING CHOPPED E GLASS AND 360 GSM E GLASS. A hybrid composite is a combination of two or more different types of fibre. Contact: +91-9008169572, +91-9008001602, 080-40969981 |

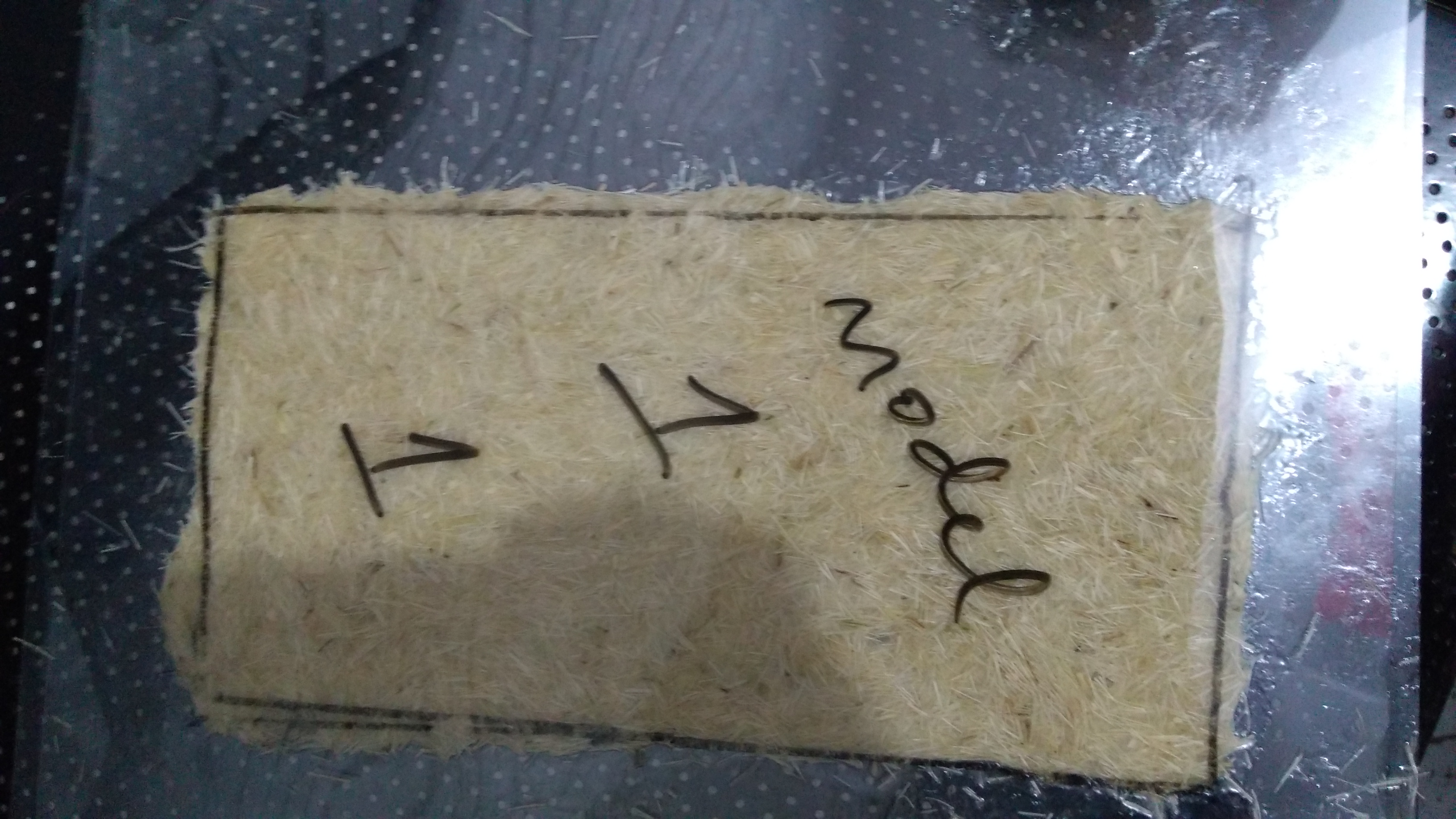

| TCM002 | DEVELOPMENT OF COMPOSITE USING COCONUT COIR AND EPOXY RESIN. Low-cost, high-quality, sustainable materials are developed using pretreated coconut coir. Contact: +91-9008169572, +91-9008001602, 080-40969981 |

| TCM003 | DEVELOPMENT OF E GLASS JUTE EPOXY REINFORCED NATURAL HYBRID COMPOSITE. E GLASS and JUTE are used in the process and developed using the hand lay-up technique. Contact: +91-9008169572, +91-9008001602, 080-40969981 |

| TCM004 | DEVELOPMENT OF EGLASS AND RUBBER POWDER COMPOSITE MATERIAL. A hybrid composite with different percentages is fabricated using hand lay-up technique. Contact: +91-9008169572, +91-9008001602, 080-40969981 |

| TCM005 | DEVELOPMENT OF E GLASS AND CHICKEN FEATHER COMPOSITE. Hybrid composites with different compositions show good strength and stiffness. Contact: +91-9008169572, +91-9008001602, 080-40969981 |

| TCM006 | DEVELOPMENT OF COMPOSITE MATERIAL USING E GLASS AND E WASTE MATERIAL. The effect of fibre loading and orientation on performance is examined. Contact: +91-9008169572, +91-9008001602, 080-40969981 |

| TCM007 | DEVELOPMENT OF COMPOSITE MATERIAL USING SUGARCANE BAGASSE, SISAL AND JUTE MATERIAL WITH ANGLE ORIENTATION. The performance of hybrid composites is evaluated. Contact: +91-9008169572, +91-9008001602, 080-40969981 |

CONTACT US

For more information and full ABSTRACT

+91 9008001602

[email protected]

Technofist provides the latest 2018 — 2019 COMPOSITE MATERIALS Projects for final year engineering students in Bangalore, India. COMPOSITE MATERIALS Based Projects with latest concepts are available for final year mechanical/electronics/computer science students.

ACADEMIC PROJECTS GALLERY